Blog: Adjustable Nozzle Ring for Radial Turbine

A Radial-in-Flow turbine is a device that converts fluid pressure into mechanical energy and is widely used in fields such as power generation, petrochemicals, and food processing. It accelerates the fluid through a nozzle, allowing the high-speed fluid to impact the impeller, driving its rotation, thereby achieving energy conversion. In the heart of the industry--the power system--the radial turbine plays a critical role. Today, let's focus on a vital component of the radial turbine--the adjustable nozzle ring, which imparts intelligence and flexibility to the turbine

Adjustable Nozzle Ring

The adjustable nozzle ring is an essential component in a radial turbine. It directs the high-temperature, high-pressure airflow from the upstream components into the impeller at a specific angle, imparting a certain circumferential velocity to the impeller.

Since the incoming flow consists of high-temperature, high-pressure gas, and the fluid medium may be somewhat corrosive, the adjustable nozzle ring must resist high temperature, corrosion, and strength. Common materials include stainless steel (SS304, 303, 316, 316L), silicon carbide, and ceramics.

The working principle of the adjustable nozzle ring is to achieve optimal matching with the machine at various speeds by changing the flow passage cross-sectional area of the turbine. In turbochargers, when the engine operates at low speeds, the nozzle ring blades can be rotated to reduce the nozzle ring's cross-sectional area, thereby increasing the turbine speed and boost pressure, ensuring sufficient boost pressure and air intake at low speeds. When the engine is operating at high speeds, the nozzle ring blades rotate in the opposite direction, increasing the cross-sectional area of the nozzle ring, thus lowering the turbine speed and preventing the turbocharger from over speeding. This design allows the radial turbine to perform optimally under different working conditions.

Radial turbines with adjustable nozzle rings are widely used in the petroleum and chemical, power generation, food processing, pharmaceuticals, metallurgy and environmental protection, energy recovery, aerospace, and automotive industries. This wide range of applications demonstrates the adjustable nozzle ring's strong adaptability.

Adjustable Nozzle Ring Diagram

Key Design Points of the Adjustable Nozzle Ring

- Geometric Parameter Optimization: The design of the adjustable nozzle ring involves multiple geometric parameters, including the inlet and outlet blade angles, nozzle length, and height. Optimizing these parameters is crucial for improving turbine performance.

- Flow Matching: The design of the adjustable nozzle ring needs to closely match the impeller's inlet characteristics to reduce flow losses and ensure that the airflow has the appropriate flow characteristics when entering the impeller.

- Internal Flow Control: The adjustable nozzle ring's well-designed internal structure effectively controls the direction and velocity distribution of the airflow, reducing flow separation and vortices and thereby improving the efficiency of pressure conversion in the gas.

Performance Advantages of the Adjustable Nozzle Ring

- High Efficiency: The adjustable nozzle ring maintains high adiabatic efficiency over a wide flow range by intelligently adjusting the nozzle outlet angle.

- Wide Flow Range: The adjustable nozzle ring's optimized design allows it to adapt to different operating conditions, providing a broad flow range.

- Compact Structure: The adjustable nozzle ring typically has a small size and weight, making it especially advantageous in space-constrained applications.

Application of TurboTides in Adjustable Nozzle Radial Turbines

TurboTides supports the entire design process of radial turbines with adjustable nozzles. This includes one-dimensional preliminary design analysis, three-dimensional parametric geometry modeling, through-flow analysis, three-dimensional CFD simulation, and finite element analysis. It also supports the automatic optimization of design schemes through an embedded intelligent optimizer.

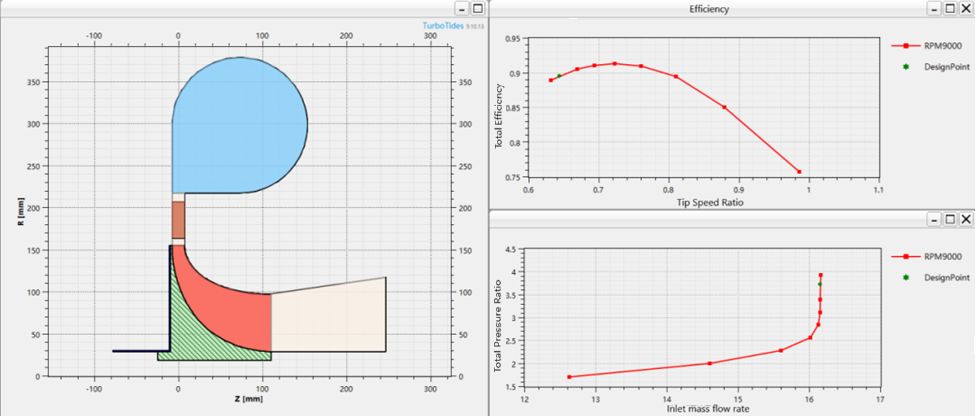

The results of the one-dimensional preliminary design analysis of a specific radial turbine using TurboTides are shown in the diagram below:

Preliminary Design

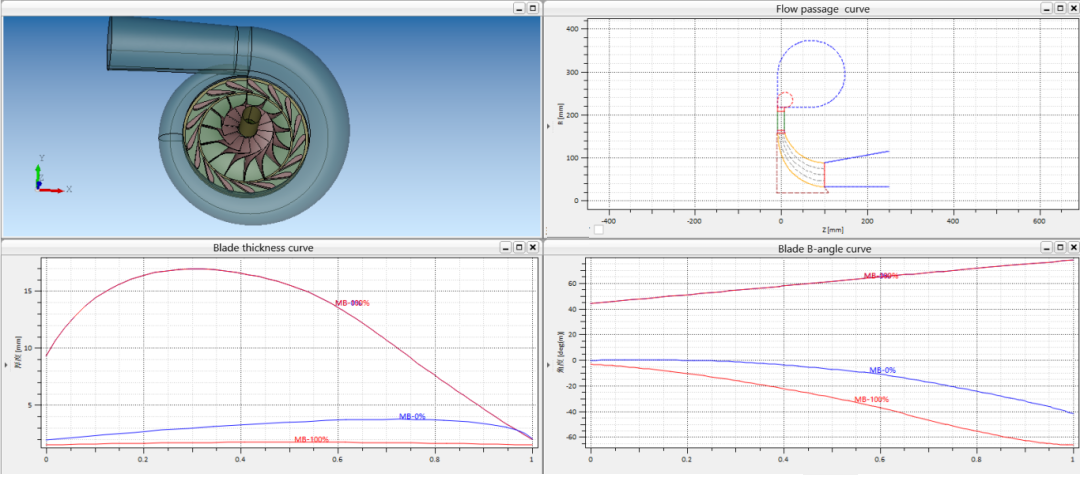

Based on the one-dimensional design results, a three-dimensional parametric geometric model can be generated with a single click, as shown in the diagram below.

Parametric Geometric Model

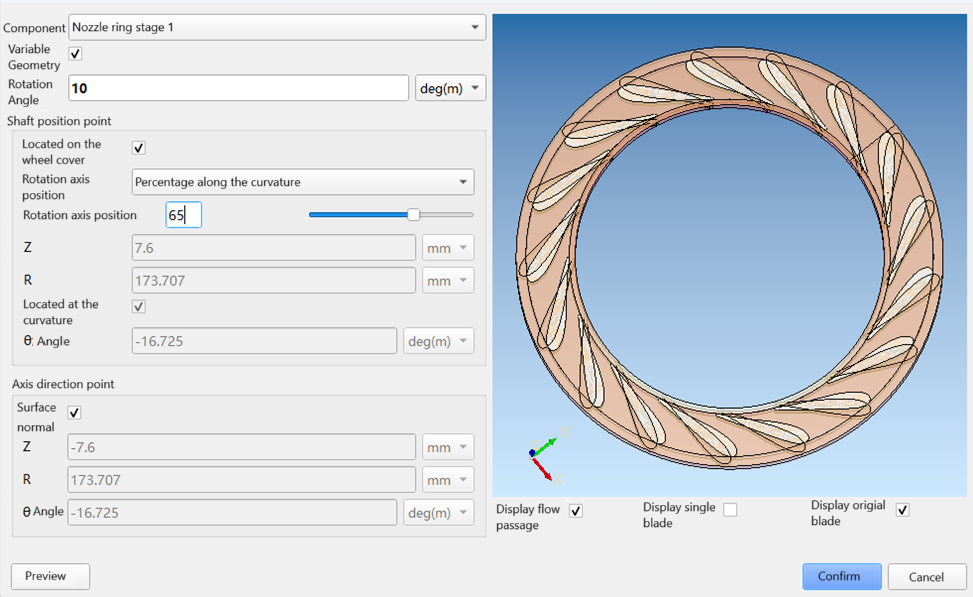

The geometric module supports the adjustable nozzle ring function, allowing users to define the axis position and rotation angle of the nozzle ring themselves, as shown in the diagram below:

Diagram of Adjustable Nozzle Ring

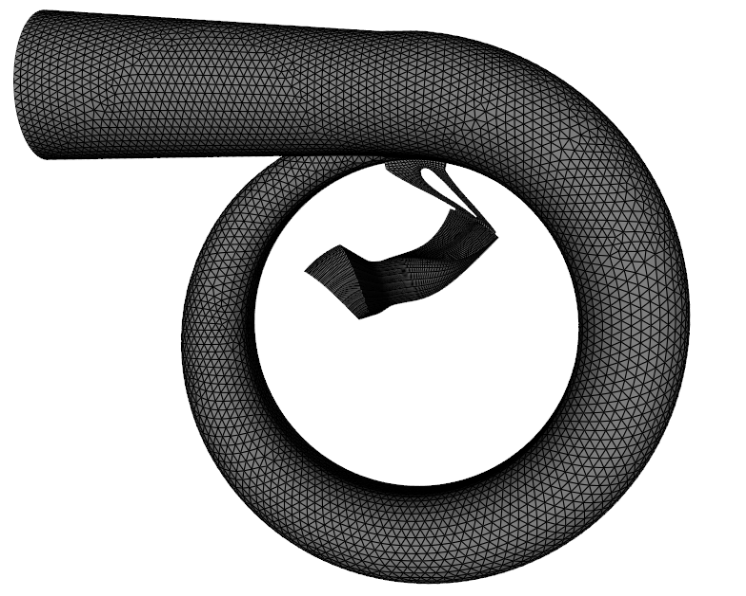

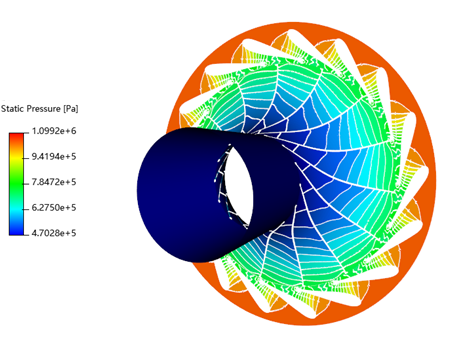

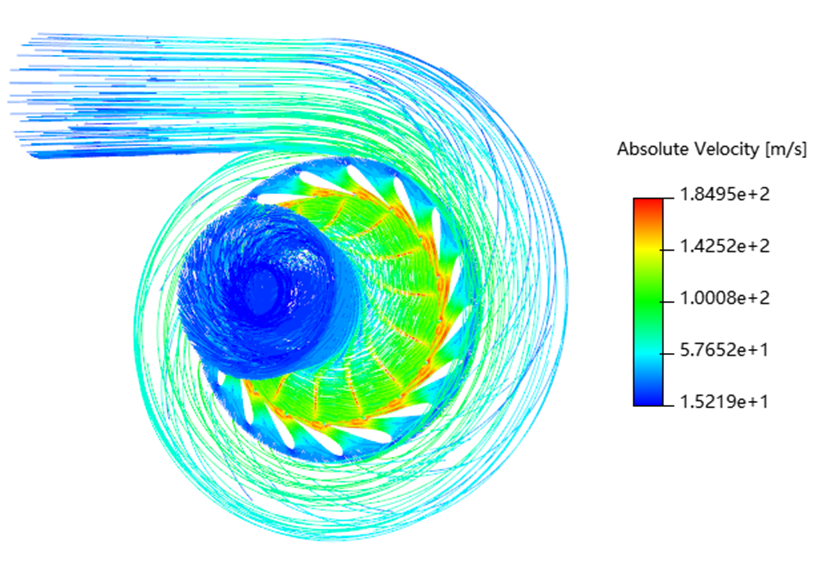

With the subsequent CFD and FEA simulation capabilities, the machine flow field performance, stress, strain, and deformation under different nozzle ring openings can be quickly calculated. The three-dimensional CFD and FEA modules can automatically generate three-dimensional fluid and solid domain meshes and obtain boundary conditions, loads, constraints, and other conditions, facilitating users in improving iteration efficiency. The three-dimensional CFD mesh and simulation result cloud plots are shown in the diagram below.

CFD Mesh and Simulation Results

The TurboTides supports the design and analysis functions of adjustable nozzle rings and radial turbines, making the forward design of radial turbines with adjustable nozzles more convenient and efficient. The parametric modeling function simplifies the modeling of radial turbines with adjustable nozzle rings, making it easy to adjust, and the seamless integration of the CFD simulation module enhances the accuracy and convenience of performance simulations. In the future, TurboTides will continue to support the role of radial turbines with adjustable nozzle rings in improving energy utilization efficiency and promoting industrial progress.

Please contact us if you have any questions or would like to schedule a live demonstration.