Software and Services

Overview

- Design System Integration

- Design Process Standardization

- On-Demand Optimization

- Design Knowledge Preservation

- 1D Meanline Design and Analysis

- 2D Through-flow and Blade-to-Blade Analysis

- Geometry Modeler

- 3D CFD Analysis

- 3D Finite Element Analysis (FEA)

- Built-in Database Support

- Easy Optimization Setup

- Cycle Analysis

Functional Modules

The TurboTides Vision

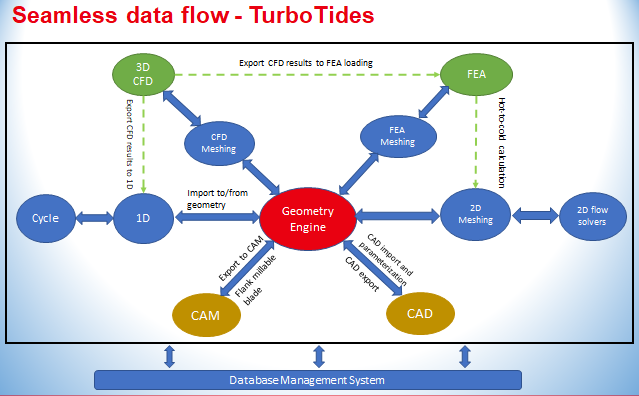

TurboTides was developed by a team of global experts with decades of experience working in the turbomachinery industry. TurboTides is not only a highly integrated, multi-disciplinary CAE package for turbomachinery design, but also a powerful platform to digitize and manage the cumulative design experience and knowledge through a unique embedded database management system.

TurboTides provides a smooth workflow from system analysis to 1D preliminary design, 3D geometry generation, automatic meshing, 3D CFD and FEA structural analysis. Furthermore, TurboTides offers extensive support for the reuse and redesign optimization of the past designs. TurboTides accomplishes these through a unique combination of parametrized CAD import, unique data reduction capability, embedded database management, and multidisciplinary design optimization, all within a single, fully integrated package.

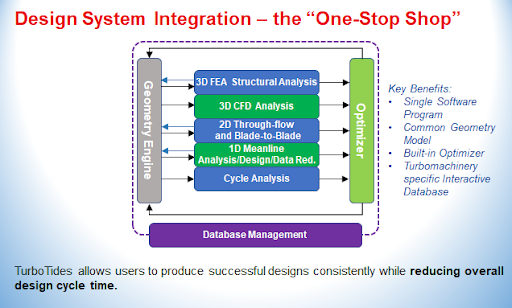

Design System Integration

TurboTides is a new software that takes full advantage of the latest and most modern engineering and software development tools and practices so that it provides a highly integrated, all-in-one R&D platform. All key functions for turbomachinery design are fully integrated into the TurboTides platform, including:

- Cycle Analysis

- 1D Meanline Design and Analysis

- 2D Throughflow and Blade-to-Blade Analysis

- 3D Geometry Generation and Blade Shaping

- CAD Import and Export Interfaces

- 3D CFD with Automatic Grid Generation

- 3D FEA for stress, thermal, and modal analysis

- Multi-level and multi-disciplinary optimization

- Knowledge Base Management

Design knowledge preservation

TurboTides provides an interdisciplinary workflow management system that enables a standardized design process. By considering aerodynamic performance, mechanical design, and manufacturing at each stage of the design process, potential issues can be addressed as early as possible in each design project.

TurboTides allows manufacturers both to standardize their design process and include multi-level optimization (from cycle, 1D, 2D, to 3D) to reduce design time, improve the design success rate, and improve the performance of their turbomachinery designs.

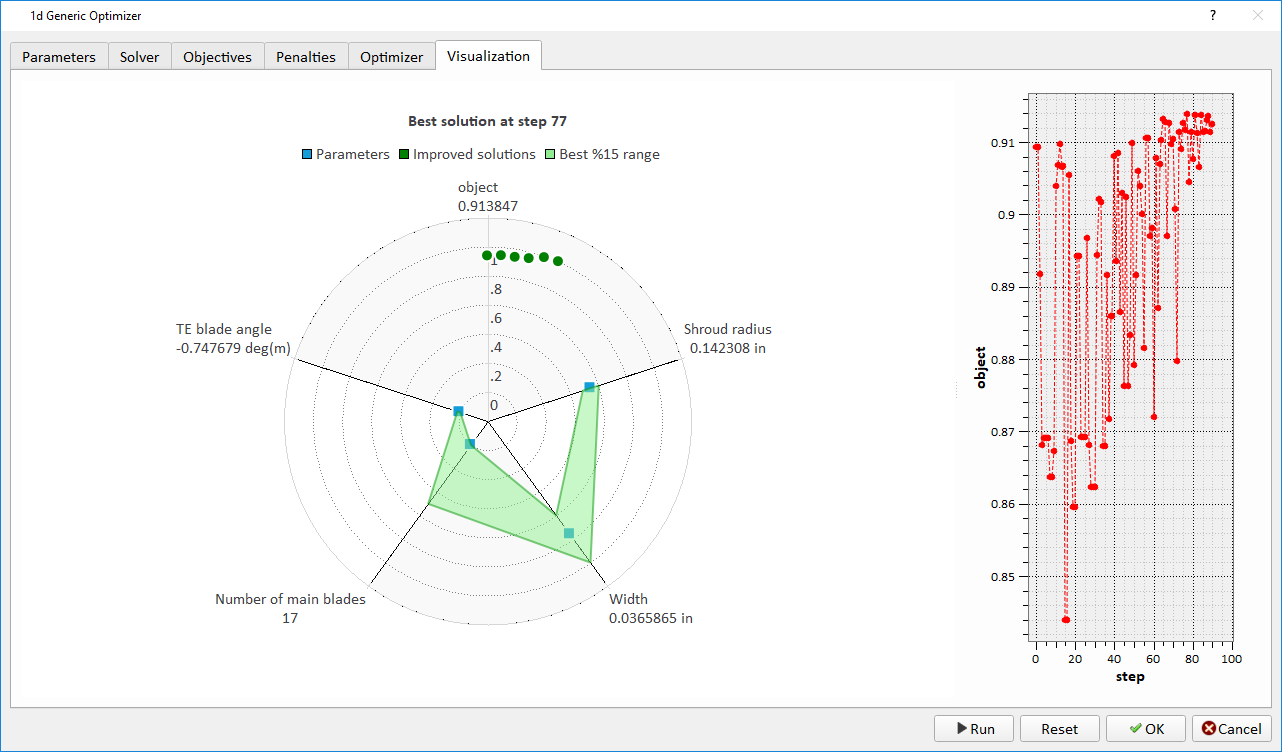

On-Demand Optimization

TurboTides allows users to conveniently setup optimization at each design stage. This is made possible through an embedded optimizer and parameterized geometry and flow model.

Furthermore, TurboTides supports Multi-Disciplinary Optimization (MDO) with its integrated system. A typical MDO project may require parameterized 3D geometry generation, automatic meshing, CFD and FEA solvers working seamlessly together, which is made possible by TurboTides all-in-one system.

Design Knowledge Preservation

The accumulation of design experience is essential for the long-term health any advanced turbomachinery manufacturer. TurboTides provides a powerful system for design experience digitization and technology management that has not previously been available to the turbomachinery industry.

With TurboTides, users can utilize proven design methods to mitigate design risks and shorten design phases. Find an existing design that is close to what is needed, for example, and do a shroud cut or radius trim to fit the new conditions. Use the advanced reverse-engineering tools to import past designs into the design knowledgebase whether they were designed in TurboTides or not.

TurboTides provides UDF (User-Defined Functions) for user’s innovations; and helps users to digitize and manage design knowledge.

Along with the preserving your organizational knowledge of turbomachinery design, TurboTides will enable the future development and application of machine learning and AI design capabilities to your turbomachinery designs.

Cycle Analysis

- TurboTides Cycle Analysis supports the design and analysis of following thermodynamic cycles and configurations:

- Rankine cycle, including Organic Rankine Cycle (ORC)

- Gas turbine cycle

- Super-critical CO2 cycle

- Refrigeration cycle

- Turbocharger matching

- Multistage compressor sizing and analysis, including Integrated Gear Compressor (IGC)

- Supports various compressor and turbine model option, such as data map or a 1D model

- Easy setup for cycle optimization

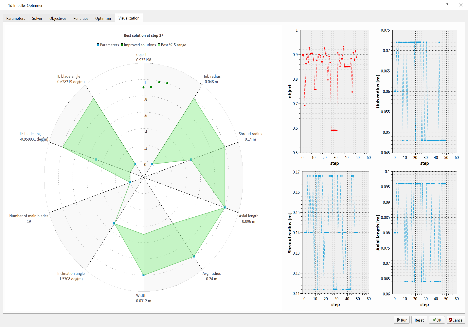

1D Meanline Design and Analysis

1D meanline module supports preliminary design, analysis and data reduction for radial, mixed-flow and axial compressors, turbines, pumps and fans.

- Calibrated 1D model through data reduction can match the test data point-by-point on full performance map.

- Real fluid model based on REFPROP 10 and fast table.

- User Define Function (UDF) allows user to change the default model and behavior of the program

- Easy setup for 1D optimization

- Supports scaling, trimming, flow-cut and adjustable geometry modeling

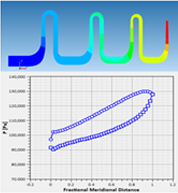

2D Through-flow and Blade-toBlade Analysis

2D flow analysis includes a hub-to-shroud throughflow (S2 surface) solver and a blade-to-blade (S1 surface) solver.

- Streamline curvature method

- Automatic mesh generation from 3D geometry

- Automatically quantify the blade geometry (blade angle, thickness, lean)

- Considers loss, deviation and blockage and spanwise mixing

- Easy setup for flow passage and blade profile optimization

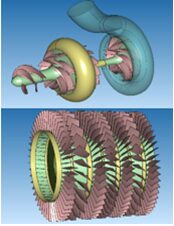

Geometry Modeler

Geometry modeler provides full support for 3D geometry generation.

- Geometry editing of common components in radial and axial compressors, turbines, pumps, blowers and fan

- Mechanical geometry editing

- CAD import of full 3D CAD geometry including flow passage, blades, impeller blades, disk and back face feature

- Embedded database supports convenient storage and reuse of any 3D component models

- Advanced volute editing capability with convenient user control of various cross section, volute tongue, exit pipe geometry and dual volute

- Supports various airfoil types, such as NACA, DCA, MCA etc

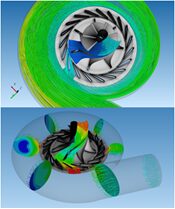

3D CFD Analysis

Full 3D pressure based CFD solver with unstructured meshing.

- Support parallel computing with unlimited cores

- Fully automatic mesh generation and setup of boundary condition

- Full post-processing support: text report, mesh/contour/vector/streamline/iso-surface view, line plots

- Support real gas calculation, including automatically generated real gas table

- Easy comparison plots between 3D and 1D results

Interface to CFX TurboGrid allows easy employment of ANSYS CFX if desired

3D Finite Element Analysis (FEA)

Support Finite Element Analysis for impeller, vane element and volute

- Support static analysis, thermal analysis and modal analysis

- Support linear and nonlinear material, including elastic, plastic, creep and hyper-elastic material

- Convenient pre-processing support: automatic mesh generation and automatic setup of loads and constraints

- Passage and blade surface loads are automatically interpolated from 3D CFD results

- Full post-processing support: text report, Campbell diagram, interference diagram, contour and deformation plots etc.

- Computation of weight and inertial

Interface to CFX TurboGrid allows easy employment of ANSYS CFX if desired

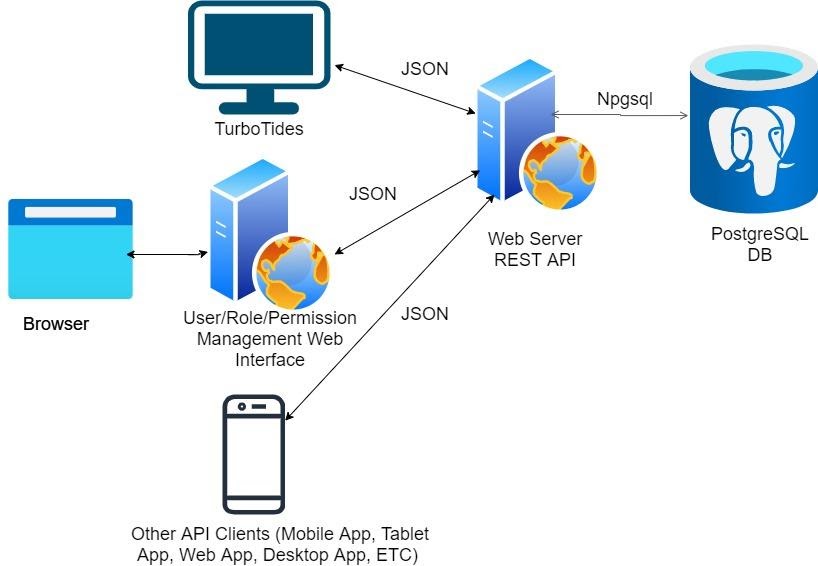

Built-in Database Support

Embedded database is a version-controlled central data storage placed on the network that facilitates the saving and reuse of design, test data, geometry models and UDF across your organization.

- Any TurboTides objects (components, machine, curves, fluid models etc.) can be saved to the database and reloaded to the current designs

- Object-oriented database records support complicated data structure from performance map to component and machine geometry and flow models

- Allow user to define any user record types and specify their behavior through scripting

Interface to CFX TurboGrid allows easy employment of ANSYS CFX if desired

Easy Optimization Setup

TurboTides built-in optimization capability provides convenient employment of optimization throughout every stage of design process.

- Can invoke cycle, 1D, 2D CFD and FEA solvers conveniently in each module

- Through scripting, user can define complex optimization procedure such as multi‑disciplinary optimization